The autumn digital edition of Automotive Logistics and Finished Vehicle Logistics magazine is out now, featuring interviews with top executives at Audi and GM, as well as insights into the latest US transport legislation.

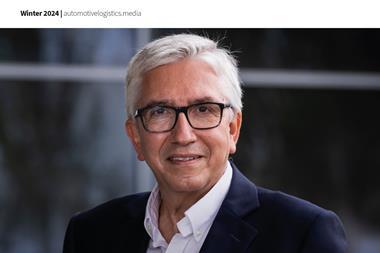

Our latest edition leads with an interview with Marco Philippi, head of procurement at Audi, who talks about the carmaker’s new supply chain code of conduct and its targets for risk-free and sustainable material sourcing. Audi is supporting its initiatives with advanced technology and collaborating more closely with suppliers to cut emissions and source more recycled materials.

We also talk to Edgard Pezzo, executive director of global logistics and containerisation, about the carmaker’s strategic focus on creating more resiliency in the supply chain. GM is coordinating that transformation across functions within its Global Purchasing and Supply Chain (GPSC) organisation – including procurement, supplier coordination, transport logistics and packaging.

Packaging at GM is also in focus in our interview with Jeremy Galanty, sustainability analyst at the carmaker, who is joined by Magna International’s director of packaging continuous improvement, Bridget Grewal. The two companies are members of the Supplier Partnership for the Environment and Galanty and Grewal discuss the latest guidance issued on reducing landfill waste from parts packaging.

The automotive industry’s new focus on strengthening a more sustainable supply chain are being backed up, or in fact driven by, government regulation. In the US this is most recently seen in the signing of the Inflation Reduction Act (IRA), which in part aims to clean up the transport industry by tying investment and tax incentives to stringent rules on local content for the manufacturing of electric vehicles.

Government legislation in the US is also having an impact on the rail freight industry, which has been suffering from capacity and labour shortages, leading to delays in the delivery of finished vehicles. US authorities are now introducing measures designed to guide the Class 1 railroads toward improved service levels as well as helping to negotiate labour disputes.

This edition also includes a full review of this year’s Automotive Logistics and Supply Chain Global conference, held in Detroit in September, including a focus on what needs to be done to recruit more women into the industry and improve conditions and opportunities.

Features include:

The benefits of a better pack mentality

Strategies for a sustainable US auto sector

Using the supply chain as a force for good at Audi

The logistics of resiliency at GM

Pushing for greater parity in the supply chain

Getting US rail shipments back on track

Disruption, risk and contingencies in the supply chain – ALSC Global review

Topics

- American Axle

- Audi

- Battery Supply Chain

- Benteler

- Carter Logistics

- Ceva Logistics

- Digitalisation

- DSV

- Editor's pick

- Electric Vehicles

- Finished Vehicle Logistics

- GM

- IAC

- Inbound Logistics

- Johnson Electric

- Joyson Safety Systems

- Kuehne + Nagel

- Logistics service provider

- Maersk

- News and Features

- Nissan

- OEMs

- Policy and regulation

- Rail

- Road

- Royale

- Ryder

- Stellantis

- Suppliers

- Supply Chain Planning

- Toyota

- Trade & Customs

- Volkswagen

No comments yet