JLR is building robust supply chains for its electric future, appointing 50 new experts to trace and secure critical materials. The move supports its goal to electrify all brands by 2030 while upholding ethical standards and production stability.

JLR has appointed 50 new specialists to improve traceability and “ethical” sourcing of critical materials across its electric vehicle supply chains, as part of a strategic move to secure production continuity and build trust in its transformation towards a fully electric model line-up by 2030.

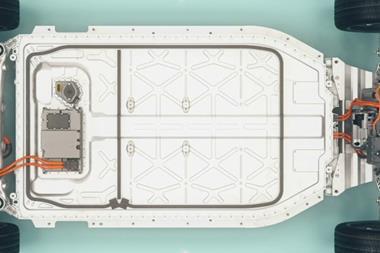

The newly created roles are focused on material mapping and data analysis, providing the company with real-time visibility over components and raw materials that underpin electric vehicle production. This includes monitoring and auditing the origins of key inputs such as lithium, cobalt, manganese, nickel and graphite, essential for battery systems and high-voltage components.

“The goal is to identify the true source of our parts so we can secure continual supply and uphold the highest supply chain standards”

- Jaspal Gill, Supply Chain Mapping and Transparency Manager, JLR

“The goal is to identify the true source of our parts so we can secure continual supply and uphold the highest supply chain standards,” said Jaspal Gill, Supply Chain Mapping and Transparency Manager at JLR, who previously worked in Material Planning and Logistics at Castle Bromwich. “Since joining I’ve trained new team members who bring their own experiences from around the business and a strong willingness to learn new skills and embrace new challenges.”

Global volatility forces supply chain refocus for JLR

JLR’s supply chain resilience strategy emerges against a backdrop of global volatility, with the automotive sector still contending with the aftershocks of the pandemic, Red Sea shipping disruption and regional conflicts. The company aims to anticipate and avoid such disruptions through greater transparency and early risk detection.

Long and complex supply routes spanning borders and jurisdictions remain particularly vulnerable to sudden shocks. JLR’s expansive network includes around 4,500 direct suppliers and highly intricate flows of materials for batteries, motors and high-voltage electronics. In this context, the newly recruited team is tasked with collecting and interpreting granular data to create a full picture of supplier tiers and raw material origins, allowing for proactive mitigation of potential stoppages and stricter compliance with emerging regulations.

JLR is also partnering with organisations that specialise in physical audits of raw materials at mine level, and is investing in digital technologies including AI, machine learning and advanced analytics to support real-time supply chain intelligence.

Read more JLR stories

- How JLR is putting sustainability at the forefront

- Restarting US shipments following pause due to tariffs: JLR

- JLR launches Innovation Challenge focused on supply chain mapping

- How JLR is Reimagining sustainable seat foam with closed-loop logistics

Upstream, “ethical” and sustainable end-to-end supply chain operations

Ama Agyewaa Sappor, who also recently joined JLR as a Supply Chain Mapping and Transparency Manager, brings 15 years of experience in supply chain operations and a strong commitment to ethical practice. “I chose to commit my skills to JLR because of its commitment to people and planet; not just profits,” she said. “Having grown up in Africa, I am passionate about our upstream impact, including ethical sourcing and sustainable end-to-end supply chain operations.

“It all starts with visibility, and that’s what my team brings to the table, contributing directly to JLR’s efforts to be a truly global citizen.”

Supercharge your supply chains with Logistics leaders across the industry

Want to dive deeper into how OEMs like GM, BMW, Mercedes-Benz, Nissan and more are rethinking supply chain transparency and resilience?

Then come and connect with industry leaders shaping the future of sustainable vehicle logistics, join the Automotive Logistics & Supply Chain Global conference this September in Detroit.

Reserve your seats now to attend the leading automotive supply chain event in North America

The recruitment initiative complements JLR’s broader investment in supply chain capability. The company has already trained more than 20,000 employees in specialist topics such as modern slavery prevention and export controls. This forms part of a £20m ($27m) annual commitment to workforce upskilling to support its transition to electrified luxury vehicles.

As JLR scales up production of electric vehicles across its Jaguar, Range Rover, Defender and Discovery brands, the resilience and transparency of its supply chain will play a critical role in meeting delivery targets and maintaining ethical standards. With global demand for battery minerals rising and regulatory scrutiny intensifying, material traceability is fast becoming a strategic differentiator in the automotive industry.

No comments yet